Printing Does Not Start/Printing Is Blurred/Colors Are Wrong/Straight Lines Are Misaligned

11-Sep-2008

8200348500

Isu

Sebab dan Solusi

When using paper with one printable surface, make sure that the paper is loaded in the Rear Tray with the printable side facing up or in the Cassette with the printable side facing down. Printing on the wrong side may cause unclear prints or prints with reduced quality.

Refer to the instruction manual supplied with the paper for detailed information on the printable side.

See [ An Error Message Is Displayed on the LCD ] to identify the ink error, and then take the appropriate action depending on the error condition.

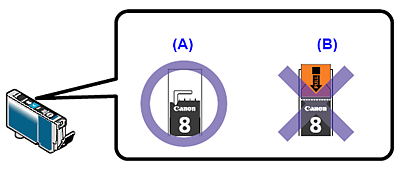

Make sure all of the protective film is peeled off and the air hole is exposed, as illustrated in (A). If the orange tape is left as in (B), pull the orange tape and remove it.

(A) Correct

L-shaped air hole is exposed.

(B) Incorrect

The tape is not peeled off.

Perform any necessary maintenance operation.

Printing the Nozzle Check Pattern

Printing the Nozzle Check Pattern

Print the nozzle check pattern to determine whether the ink ejects properly from the print head nozzles.

Print Head Cleaning

Clean the Print Head if lines are missing or if white streaks appear in the printed nozzle check pattern. Cleaning unclogs the nozzles and restores the print head condition. Note that cleaning the Print Head causes used ink to be absorbed in the ink absorber. Cleaning the Print Head consumes ink, so perform Print Head Cleaning only when necessary.

See[Print Head Cleaning]

Print Head Deep Cleaning

If print quality does not improve by standard Print Head Cleaning, try Print Head Deep Cleaning, which is a more powerful process. Note that cleaning the Print Head causes used ink to be absorbed in the ink absorber. Print Head Deep Cleaning consumes more ink than standard Print Head Cleaning, so perform this procedure only when necessary.

If you did not align the Print Head after installation, straight lines may be printed misaligned. Make sure to align the Print Head after you install it.

See [ Automatic Print Head Alignment ] and perform Automatic Print Head Alignment. If this does not solve the problem, see [ Manual Print Head Alignment ] and perform Manual Print Head Alignment.